In the intricate dance of manufacturing, precision is paramount. As industries evolve, so must the tools at their disposal too. Enter laser cutting technology – a revolutionary force that has reshaped the manufacturing landscape.

Gone are the days of laborious manual cutting; laser cutting has emerged as the vanguard of efficiency and accuracy. In this article, we delve into the myriad benefits that laser cutting brings to the manufacturing table.

Precision Personified

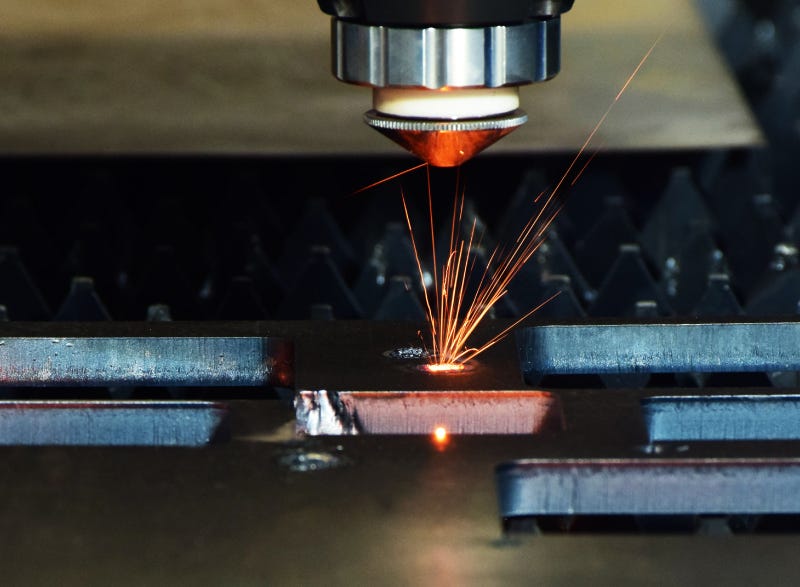

At the heart of laser cutting technology lies an unparalleled precision that sets it apart. Traditional cutting methods often suffer from the vagaries of human error and wear and tear of machinery. Laser cutting, on the other hand, is a symphony of exactitude.

The laser beam, guided by intricate computer algorithms, slices through materials with micron-level precision, ensuring the creation of intricate designs and complex patterns that were once deemed unattainable.

Versatility Unleashed

laser cutting perth is the chameleon of manufacturing, seamlessly adapting to a diverse array of materials. From metals and plastics to fabrics and ceramics, the laser beam is a master of all trades.

This versatility opens up a world of possibilities for manufacturers, allowing them to explore new materials and push the boundaries of design. Laser cutting, quite literally, cuts through the limitations of traditional methods.

Speeding Ahead

In the fast-paced world of manufacturing, time is of the essence. Laser cutting technology emerges as the speedster, drastically reducing production times. The laser beam, swift and unerring, can traverse materials at incredible speeds, ensuring that projects move from conception to completion in record time.

This not only enhances efficiency but also allows manufacturers to meet tight deadlines and stay ahead in the competitive race.

Cost-Efficiency Redefined

While cutting-edge technology often comes with a hefty price tag, laser cutting manages to be a beacon of cost-efficiency. The precision of laser cutting minimizes material wastage, ensuring that every cut counts.

Moreover, the speed at which laser cutting operates translates to reduced labor costs. Manufacturers find themselves not only producing higher quality products but also doing so at a fraction of the cost compared to traditional methods.

Environmental Friendliness

In an era where sustainability is non-negotiable, laser cutting technology steps up as an eco-friendly alternative. Traditional cutting methods often involve a plethora of chemicals and produce substantial waste.

Laser cutting, however, is a clean process that generates minimal waste and eliminates the need for harmful chemicals. This not only aligns with environmental goals but also positions laser cutting as a responsible choice for manufacturers looking to reduce their carbon footprint.

The Role of Laser Cutting in Hydraulic Cylinder

hydraulic cylinder repair lisle il is a critical aspect of many manufacturing processes, and laser cutting technology plays a pivotal role in this domain. The demand for efficient hydraulic cylinder repair is met with the precision of laser cutting.

The technology ensures that cylinder components are cut with utmost accuracy, facilitating seamless repairs, and extending the lifespan of hydraulic systems.

Conclusion

As we navigate the intricate web of manufacturing, laser cutting technology stands as a testament to human ingenuity. Its precision, versatility, speed, cost-efficiency, and environmental friendliness make it an indispensable tool in the modern manufacturing arsenal.

In Lisle, IL, and beyond, laser cutting is not just a technology; it’s a transformative force that propels industries into a future where perfection is not an aspiration but a standard.